Education

Keeping CO2 out of Schools

The commercial construction industry accounts for nearly 40 percent of energy-related carbon emissions annually. Knowing the impact they can have on emissions reductions, superintendents and facilities directors of large school systems have been focused on the operational carbon footprint of their buildings for years.

A Focus on Operational Carbon

Schools have focused on operational greenhouse gas (GHG) emissions so much so, that at the 2024 Green Schools Conference, attendees had the opportunity to learn more about the benefits of and challenges associated with creating a “net-zero” school in a session titled “Making Dollars & Sense Out of Decarbonization by Denser and Salt Lake City School Districts.”

And, while schools that prioritize energy efficiency may save up to $100,000 per year in utility costs, many school districts may find it hard to gain upfront funding. However, school districts can take advantage of federal funding included in the Inflation Reduction Act of 2022, which provides tax credits for schools that invest in clean energy or energy-saving projects, such as solar panels and heat pumps.

Though operational emissions (operational carbon) account for most of a building’s environmental footprint, embodied carbon emissions account for about 30 percent of a building's total emissions and should not be dismissed in new builds or renovations.

Embodied Carbon – The Other Piece of the Emissions Puzzle

Embodied carbon refers to the emissions associated with the full life cycle of a product – from raw material extraction, production, transportation, use, maintenance and end of life.

School districts should consider both the carbon impact of the exterior and interior products used in new construction or renovation.

Measuring Embodied Carbon

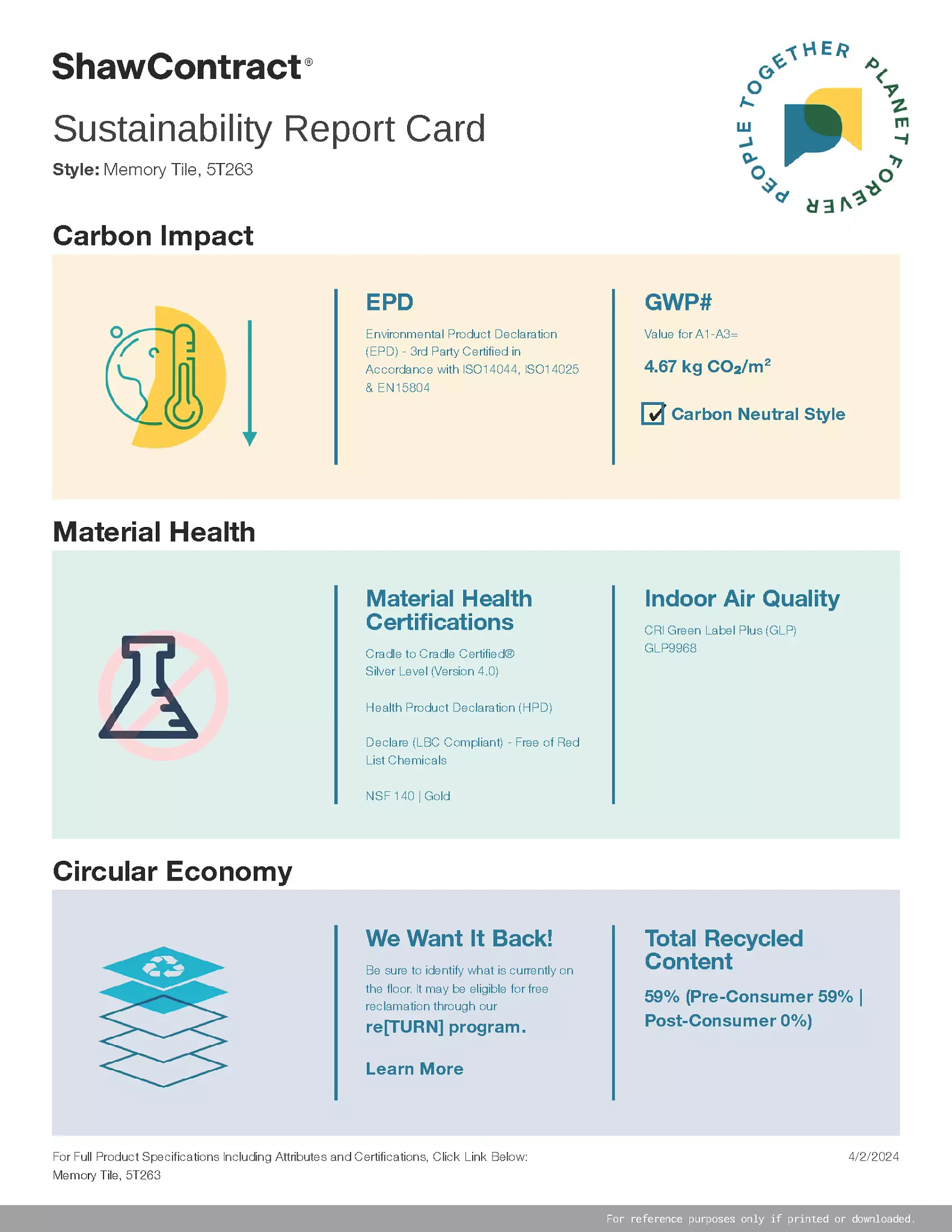

Manufacturers focused on reducing the impact of their products, measure their emissions and are transparent about their environmental footprint. To measure a product's embodied carbon, manufacturers conduct a Lifecycle Assessment. From this comprehensive document, an Environmental Product Declaration (EPD) can be created, which is a widely used tool to more easily understand the carbon impact of a product.

An EPD is a standardized, third-party verified document that offers transparent and credible data and information about a product’s environmental impact. EPDs report a Global Warming Potential (GWP) estimate for the life of the product, which is the amount of greenhouse gas impact.

The lower the GWP, the less impact the product has on a building’s embodied carbon footprint.

Shaw Contract makes it even easier for facilities professionals and designers to find low-carbon products through the “carbon impact” filter on our website. Additionally, the “sustainability report card” on the Shaw Contract website offers a quick overview of a product’s GWP and recyclability.

%20%20(pdf%20generated%20on%204_2_2024).jpg?crop=true&anchor=0,27&q=80&color=ffffffff&u=dawupc&w=1583&h=1972)

Recycling

Superintendents and facilities professionals should also consider whether a product can be recycled at the end of its useful life. Shaw Contract has been taking back and recycling EcoWorx® -backed carpet tile since 2006. And last year, Shaw announced all Shaw-manufactured resilient products can be recycled as part of the company’s re[TURN]® Reclamation Program. The more product returned to Shaw, the lower the carbon footprint of future flooring products.

Carbon is just one aspect of the environmental impact of a product. The materials needed to make a product and how the product impacts people should also be considered as part of a comprehensive approach to product sustainability. After all, what's good for students and teachers can also be good for the planet.

April 15, 2024

By using our site you accept our terms of use and privacy policy.

By using our site you accept our terms of use and privacy policy.